DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9

DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Plated Grade 8.8 10.9

Nkọwa

Ngwa ngwaNzaghachi

Ngwa ngwaNhota

Ngwa ngwaNnyefe

Njikere ibuga mbupu

10000+ SKU n'ụlọ nkwakọba ihe

Anyị na-akwado maka ihe RTS:

70% ihe ndị a napụtara n'ime 5 ụbọchị

80% ihe ndị a napụtara n'ime ụbọchị 7

90% ihe ndị a napụtaran'ime ụbọchị 10

Nnukwu iwu, biko kpọtụrụ ndị ahịa

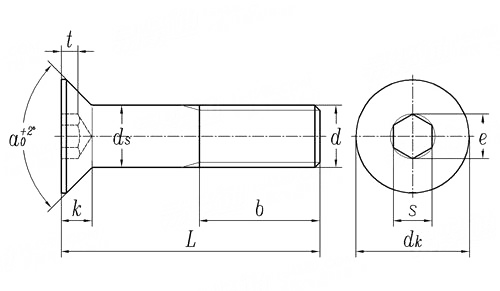

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Mgbapụta | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | tol (+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125 ml ≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L >200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Oke = Ọnụ ọnụ | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Oke = Ọnụ ọnụ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9,78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Oke | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Aha aha | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Oke | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Oke = Ọnụ ọnụ | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9,87 | |

Nkọwa zuru ezu

Ihe nkwụnye ike dị elu ga-emepụta crispness mgbe galvanized.Achọrọ nlebara anya pụrụ iche.

A na-ejikarị mgbawa mmiri na-egbu oge n'okpuru nrụgide na-egosipụta mgbawa mmiri hydrogen.Enweela isi iyi ụgbọ ala, ndị na-asa akwa, kposara, isi iyi akwụkwọ na akụkụ ndị ọzọ galvanized, n'ime awa ole na ole ka agbajichara mgbakọ, oke mgbaji nke 40% ~ 50%.N'ime usoro nke iji akụkụ cadmium-plated nke ngwaahịa pụrụ iche, e nwere mgbawa mgbawa, na e doziri nsogbu isi nke mba na usoro nhazi mmiri mmiri siri ike.Ke adianade do, e nwere ụfọdụ hydrogen embrittlement adịghị egosi egbu oge mgbawa onu, dị ka: electroplating hanger (steel waya, ọla kọpa waya) n'ihi ọtụtụ ugboro nke electroplating na pickling plating, hydrogen penetration bụ ihe dị njọ karị, na-apụtakarị na ojiji a n'ogige atụrụ ga- mee ihe mgbaji gbajiri agbaji;Ihe nkedo nke egbe egbe, mgbe ọtụtụ oge chroming gasịrị, dara n'ala ma gbajie;Akụkụ ụfọdụ agbanyụchara (nnukwu nrụgide dị n'ime) ga-agbawa mgbe a na-akụ mkpụrụ.Akụkụ ndị a bụ hydrogenated nke ukwuu na mgbawa na-enweghị nrụgide mpụga, nke a na-apụghịkwa iji weghachi ike nke mbụ site na mmịpụta mmiri.

Ka ike ihe dị elu dị elu, ka ahụ na-enwe mmetụta mgbaka mmiri hydrogen.Nke a bụ echiche bụ isi nke ndị na-ahụ maka ọgwụgwọ elu ga-eme ka o doo anya mgbe ha na-achịkọta nkọwapụta usoro electroplating.Steels nwere ike ike σb>105kg/mm2 chọrọ site n'ụkpụrụ mba ụwa kwesịrị idobe nrụgide tupu plating na ọgwụgwọ dehydrogenation post-plating kwesịrị ekwesị.Ụlọ ọrụ ụgbọ elu French chọrọ ọgwụgwọ dehydrogenation kwekọrọ maka akụkụ ígwè nwere ike σs> 90kg / mm2.

N'ihi ezi akwụkwọ ozi n'etiti ígwè ike na ekweghị ekwe, ọ bụ ihe kensinammuo na adaba ikpe na hydrogen embrittlement uche nke ihe site ekweghị ekwe ka ike.N'ihi na eserese ngwaahịa zuru oke na usoro nhazi kwesịrị ka ejiri nchara sie ike.Na electroplating, anyị chọpụtara na ike nke ígwè gburugburu HRC38 malitere igosi ihe ize ndụ nke hydrogen ebrittlement mgbaji.Maka akụkụ dị elu karịa HRC43, a ga-atụle mmiri n'ime mmiri mgbe etinyere ya.Mgbe isi ike dị ihe dị ka HRC60, a ghaghị ime ọgwụgwọ dehydrogenation ozugbo a gwọchara ya n'elu, ma ọ bụghị ya, akụkụ ígwè ga-agbawa n'ime awa ole na ole.

Nkwakọ ngwaahịa

Gbasara anyị

* Eserese na-esote na-achọpụta ụdị incoterms azụmaahịa dị iche iche.Biko họrọ nke masịrị gị.

Ngwaahịa ire ere

Ogo mbụ, echekwara nchekwa